Traction Coatings

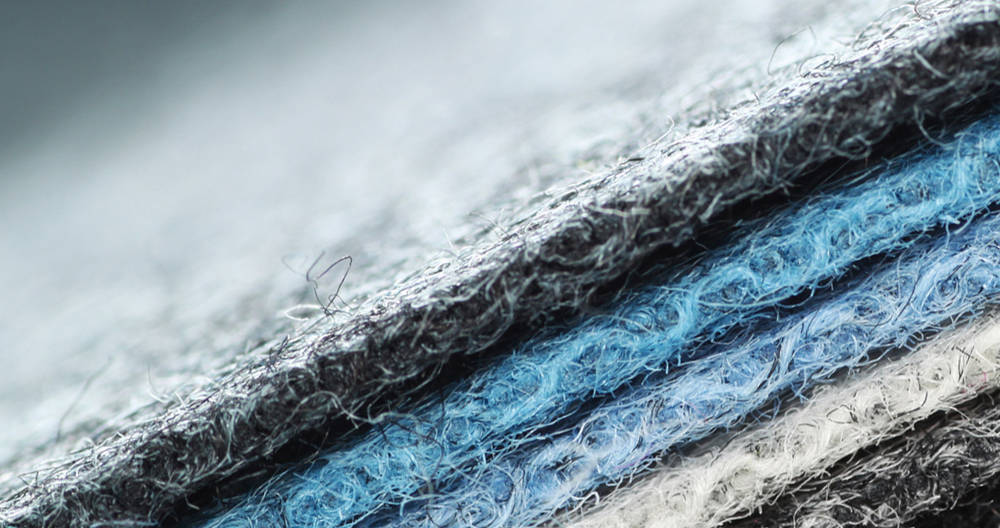

When different coating processes and materials are combined, specific properties of a component surface structure and roughness can be modified. Materials made of fabric, plastic and paper are transported more reliably and with fewer interruptions when components are treated with Impreglon's traction coatings.

In all but a few applications, the traction coating applied is a PlasmaCoat®. The PlasmaCoat® process applies a metal or a ceramic onto the substrate. The metal or ceramic thickness and roughness can be altered as desired. In addition, some PlasmaCoatings have an angular surface texture and some have spheroidal peaks (to avoid snagging in non-woven applications).

The most successful PlasmaCoat® traction coating is based on Tungsten Carbide. The roughness can be varied according to the application, but the net result is a very hard wearing traction coating. Where hard wearing traction coatings are applied to drums, cylinders or rolls (these being the most common parts to be given a traction coating), the PlasmaCoat® is applied semi-automatically which helps give a very uniform and controlled traction coating thickness. For more information see PlasmaCoat®.

For more information about Impreglon and our products call us on +44 (0) 1623 753 107 or complete our enquiry form.