Impreglon UK Industrial Batch Coaters

Impreglon UK

Industrial Batch Coaters

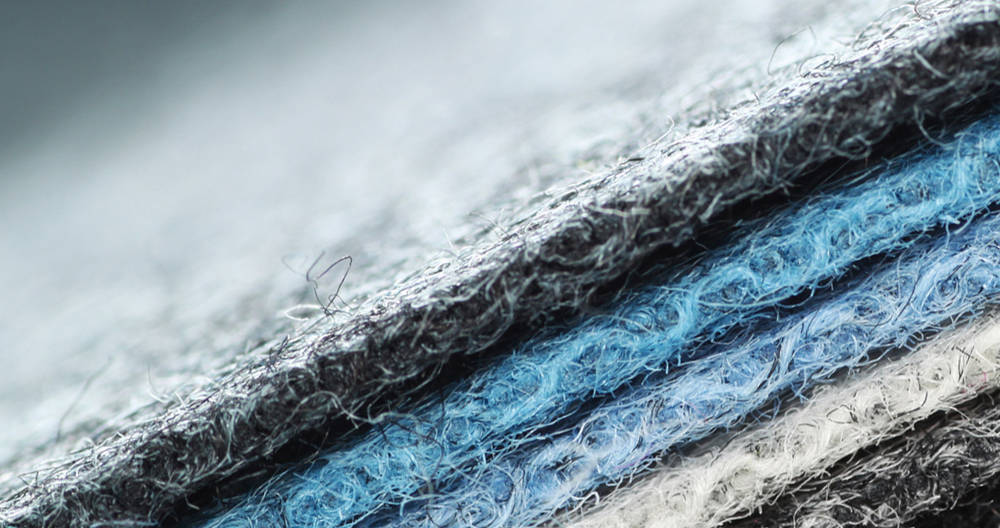

With over 30 years of coating application experience, we look forward to continuing to work with our existing clients and we welcome all forthcoming new clients. We are the UK facility of a world renowned industrial applicator of fluoropolymer, polyurethane, anti-microbial and thermal spray coatings. Impreglon UK's systems, experience and high level of service can help you solve your surface technology requirements. With our decades of experience, Impreglon UK is the fluoropolymer and thermal spray coating applicator for the UK and Ireland.

With a typical 5 to 7 working day turnaround and the option of weekend and Bank Holiday working, our commitment to serving you is unrivaled. So if you have a coating need please call or email us - we'll always give you the best coating solution advice.

Accredited to ISO 9001:2008, ISO 14001:2004 and a part of the world renowned Impreglon Group, with dozens of locations across multiple countries on four continents, our range includes, amongst others: the full Teflon®, Xylan® and Greblon® ranges, PTFE, PFA, FEP, ETFE, ECTFE (Halar®), Polyurethane, ceramic spray and metal spray (Zinc, Aluminium [TSA], stainless steel, Nickel alloy and Tungsten Carbide). An exciting and hugely successful coating is the SafeCoat 600 series. This is a highly effective decorative anti-microbial coating.

Impreglon Japan is promoting it's new generation of sol-gel coating, Silicera Coat 8011. This coating technology is available from Impreglon UK. Call us to find out more.

Optical Coating Technologies, a subsidiary of Impreglon UK, applies the SafeCoat 400 series coatings, a comprehensive range of abrasion resistant, chemical resistant, graffiti resistant and anti-fog coatings for use on plastic components.

An extensive range of coated Polycarbonate sheet is also stocked, ready to be either sold as cut down sheets or CNC routed profiles. Optical Coatings is the UK and Ireland stockholder and distributor for KRD of Germany.

Through our Optical Coatings facility, located just 6 miles from Impreglon UK, we can offer Gold, Silver, Copper and Aluminium coating of flat plastics. These coatings are deposited in a vacuum chamber and have a purity of 99.99%.

Our coatings are used wherever there is a need for low friction, non-stick, traction, high friction, easy clean, hardness, cleanliness, aesthetics, chemical resistance, corrosion resistance, solvent resistance, impact resistance, sound deadening, insulation or anti-fog. Food and medically safe coatings are available for most of these applications.

Address & Contact Details

Clover St • Kirkby in Ashfield

Sutton-in-Ashfield • NG17 7LJ

United Kingdom

+44 (0) 1623 753 107